Home » Posts Page » Blog » Codefine » Designing Bulk Bags for Automation: Compatibility with Modern Filling Equipment

You can’t just toss any bulk bag into your automated line and expect magic to happen. Success starts with bags built specifically for machines, not human hands.

Ever tried fitting a square peg in a round hole? That’s exactly what happens when dimensions aren’t spot-on with your bulk bags. While your team members can make quick adjustments on the fly, machines simply can’t.

Your automated systems need bags with rock-solid consistency during filling. It’s not just about height-the body diameter needs to stay uniform, spouts must sit exactly where they should, and corner loops need precise positioning from bag to bag. Those tiny variations that wouldn’t cause a hiccup in manual operations? They’re automation killers.

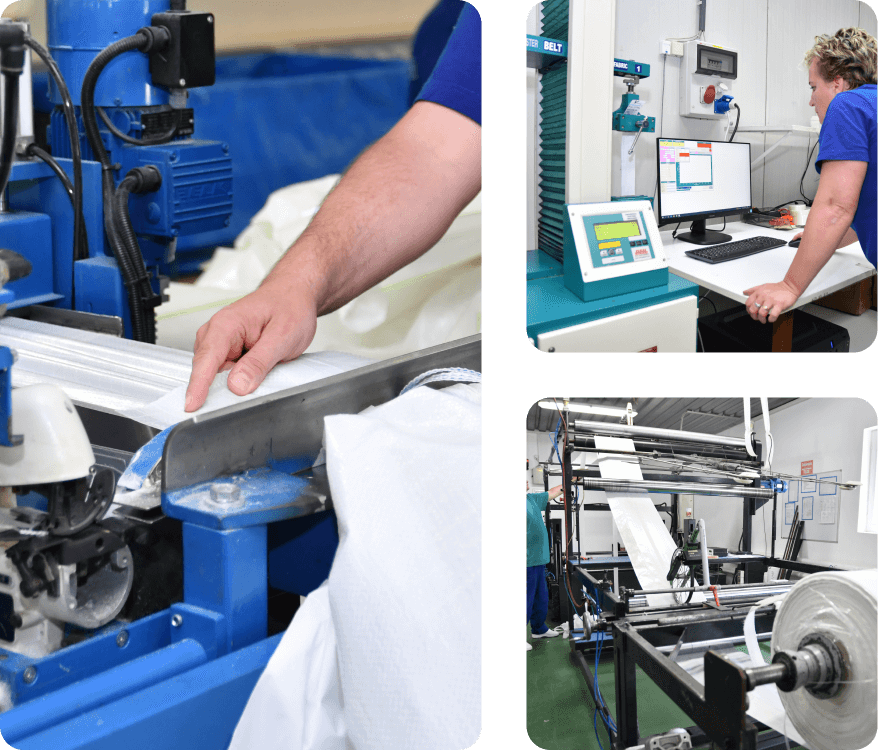

Codefine uses specialized woven polypropylene with advanced weaving techniques and strategic reinforcement in just the right places. The result? Bags that keep their shape even when your automated equipment puts them through their paces during filling.

The connection points between your equipment and bags need serious thought. You might get by with basic spouts when filling manually, but automated systems won’t be so forgiving.

On the inlet side, your spouts need perfect diameter matching with fill heads. The attachments must be tough enough to handle repeated mechanical coupling without failing. You want dust-tight seals that work with your equipment’s connectors, plus quick-connect features that save precious minutes during changeovers.

Discharge spouts need special attention too. Look for self-sealing mechanisms that keep the product where it belongs during transport. Your automated emptying stations will appreciate easy-open designs. Just like inlet spouts, discharge points need reinforced construction and precise positioning to work smoothly with unloading equipment.

The fabric making up your bulk bag isn’t just about holding product- it needs to work harmoniously with machinery. Your material needs just the right slip characteristics so mechanical handlers can grip properly. Some products demand static dissipative properties to prevent dangerous charge buildup. High-speed operations need fabrics with serious tensile strength, while hot-filled products require heat resistance.

If you work in food, pharmaceuticals, or chemicals, you face additional regulatory hurdles. Through their global sourcing network, Codefine tracks down specialized fabrics that satisfy regulatory requirements without compromising equipment compatibility.

When your production demands ramp up, standard bags often become the bottleneck. True speed requires specialized designs.

Most filling issues can be traced back to inlet spout limitations. Traditional designs often restrict flow, create dust clouds, or lose connection when filling pressures increase.

Advanced designs solve these problems with wider diameters for increased flow, shapes that guide product smoothly, reinforced attachment points that stay put under pressure, and multi-layer construction that handles continuous use without breaking down.

Some powders and granules work better with specialized filling sleeves that reach deep into the bag, directing product flow to improve density and reduce air pockets. This becomes especially valuable for fine powders that behave almost like liquids during filling.

An unstable bag during filling spells disaster for automation. When bags shift during the process, they often misalign with filling heads or jam equipment completely.

Good stability starts with corner loops positioned for balance, base designs providing a solid platform, body construction maintaining shape throughout filling, and sometimes specialized internal supports for particularly troublesome products.

For the toughest applications, Codefine builds Form Stable FIBCs with structural elements woven right into the design, ensuring the bag keeps its intended shape from start to finish.

Even the best-designed bags face integration hurdles. Anticipating these challenges saves major operational headaches down the road.

Dust control remains a persistent issue in powder handling. Modern automated systems typically build dust collection into the fill head, requiring bags designed with this in mind. Specialized spout configurations with tight seals, dual-layer dust skirts, or built-in filter elements dramatically improve air quality while keeping product where it belongs.

Weighing system integration presents its own set of challenges. Accurate weighing requires eliminating mechanical interference between bag and scale. The best bags for automated weighing incorporate suspension points allowing free movement during weighing without losing alignment with filling equipment.

Other integration factors worth considering include compatibility with positioning systems, material handling characteristics suited to your conveyor setup, discharge mechanisms synchronized with downstream processes, and surfaces that work well with automated tracking methods.

Working hand-in-hand with equipment manufacturers during bag design often reveals potential problems before they become expensive realities on your production floor.

Each industry brings unique demands to bulk packaging. Smart customization makes the difference between mere compatibility and truly optimized performance.

Food processing demands bags manufactured in clean room environments, constructed from food-grade polypropylene, often featuring FDA-compliant liners for direct food contact, and using specialized closures that maintain strict hygiene standards.

Take dairy powder operations, where aseptic filling and moisture protection aren’t negotiable. Codefine food-grade FIBCs incorporate barrier liners, spout designs specifically engineered for food applications, and construction techniques preserving product integrity while still connecting smoothly with food industry filling equipment.

Chemical and pharmaceutical applications raise the stakes with needs for static dissipative or fully conductive constructions (Type C and Type D FIBCs), UN certification for hazardous materials, comprehensive lot traceability documentation, and multi-layer construction providing superior protection.

Pharmaceutical applications frequently require extensive documentation validating material purity and manufacturing conditions. Codefine pharmaceutical-grade bags satisfy these stringent requirements without sacrificing compatibility with the specialized filling equipment these regulated industries rely upon.

Consistent performance with automated equipment doesn’t happen by accident – it requires disciplined quality control throughout design and production.

Before full implementation, thorough testing validates how bags will perform with specific equipment. This includes precise dimensional verification, compatibility testing with actual filling equipment, cycle testing to confirm durability over repeated use, and load stability testing during filling and handling.

Many operations benefit from small production trials before committing to large quantities. These modest initial runs identify potential interface issues and allow for design tweaking before scaling up to full implementation.

Once implemented, ongoing monitoring helps spot opportunities for improvement. This includes watching fill rate performance, evaluating dust control effectiveness, checking bag stability throughout filling cycles, and tracking material yield against waste.

Regular review of these operational metrics helps quantify the real economic impact of specialized bag designs while pointing toward areas ripe for further optimization.

Codefine International SA applies global expertise to the challenge of integrating bulk bags with automated filling equipment. Their manufacturing capabilities span multiple continents, enabling delivery of specialized packaging solutions matched precisely to equipment requirements.

Their approach begins with analyzing specific filling equipment specifications, operational objectives, and product characteristics. This comprehensive assessment guides their custom design process aimed at maximizing both compatibility and efficiency.

Codefine’s FIBC solutions encompass custom-engineered bags for specialized filling equipment, Type A, B, C, and D FIBCs for varying hazard levels, and specialized constructions including baffle bags, form stable designs, and circular woven options. Their industry-specific solutions span agriculture, chemicals, construction, food, pharmaceuticals, and mining.

Through collaborative design, Codefine helps organizations achieve optimal balance between equipment compatibility, operational efficiency, and cost considerations.

Keen to discuss your requirements in more detail? Get in touch with the team today to discuss our products in more detail or to arrange a quote.