Home » Posts Page » Blog » FIBC Baffle Bags: Comprehensive Overview

FIBC bulk bags are used in many different industries, with these heavy-duty containers ideal for storing and transporting large quantities of material.

FIBCs come in many shapes and sizes, with plenty of scope for customization. However, one drawback of standard bulk bags is that they tend to bulge when filled to capacity. Businesses dealing with high-value commodities will want to avoid this, as bulging sides can quickly lead to spills and stackability issues. While this problem can be avoided by underfilling bulk bags, this approach isn’t particularly practical or cost-effective.

Fortunately, an alternative FIBC solution is on hand to help. FIBC bags with baffles have a form-stable design that dramatically increases the strength and stackability of containers, as well as their storage capacity. Below, we’ll explore what sets FIBC baffle bags apart from traditional bulk bags, along with a breakdown of how they can enhance your operation.

If you’re already using FIBCs, you’ll understand the importance of selecting the right bulk bag for your requirements.

Type A FIBC bags are ideal for everyday applications in non-hazardous environments, but are a no-go when it comes to transporting anything flammable. For those, you’ll need a conductive FIBC, such as a Type C bag. As well as selecting a bag with adequate safety credentials, you also need to carefully consider the structure and build when choosing a bulk bag. If you’re short on space and need something stackable to streamline workflows, a baffle bulk bag is the obvious choice.

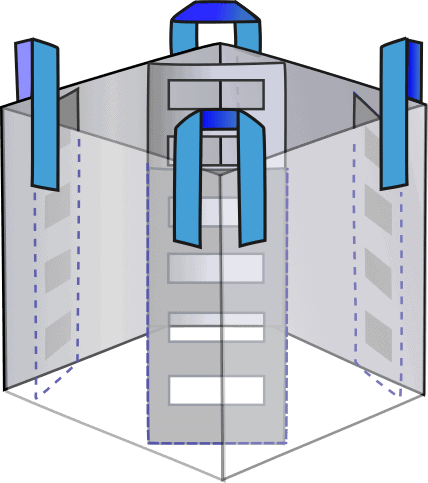

At first glance, a baffle FIBC can look identical to a standard bulk bag. However, these similarities are only superficial. Unlike their standard counterparts, baffle FIBCs feature additional panels in their corners, ensuring your bag retains its shape, even when fully filled.

There are several types of baffle bags out there. One of the most popular is the U-panel baffle bag. This bag is made up of three individual sections, with one fabric panel serving as the base and two sides of the container. A further two pieces of material are then added, creating a complete FIBC.

Another option is a circular baffle bag. These tubular containers are made of a single piece of polypropylene material, which serves as the sides. Additional fabric is then added at the base of the main body, with the only stitching found at the top and bottom of the bag. Despite having a rounded appearance when empty, this type of bag takes on a square-shaped form when filled.

Finally, there are 4-panel baffle bags. These bags feature the most individual components, with four individual sections stitched together to form the sides of the container. Although all of the baffle bags outlined above maintain a relatively square shape when filled, the 4-panel baffle FIBC has the straightest edge, making it the best choice for stackability and storage.

There are many reasons to consider making the switch from a standard bulk bag to a baffle FIBC bag. Even if you’re using a flexible intermediate bulk container marked as UN-certified, the benefits of baffle bags make them an easy choice.

The distinctive design of baffle bags means they’re a good option for companies looking for a more efficient packaging and haulage solution.

Stacking multiple baffle bags is simple, making them perfect for storage facilities with limited square footage. Once filled, baffle bags take on a square shape, increasing stability and significantly enhancing storage capacity.

Baffle bags are also designed with user-friendliness in mind. With a variety of lifting loop designs available, incorporating baffle bags into your operation will streamline everyday processes and speed up workflows. Baffle bags can be further customized with an array of top designs. Duffle tops prevent leaks and spills while protecting against contamination. Another option is a spout top. When combined with the right machinery, spout tops keep waste to a minimum during discharging and filling. They also prevent excess dust from escaping into the environment.

A more versatile form of FIBC, baffle bags can be used across almost any industry. Whether it’s the agricultural sector, a large-scale construction project, or you’re looking for food-grade packaging, bespoke baffle bags can be tailored to accommodate just about any application. Additionally, many baffle bags can be reused and recycled once they’ve reached the end of their operational life, making them a more sustainable option.

While many businesses use bulk bags because of their versatility, they do come with several limitations. One particular problem with standard FIBCs is their flexible construction. Once filled, the sides of a standard bag can bulge, with an FIBC losing its distinctive square shape. This causes all manner of issues when it comes to stacking and stability, making them impractical for smaller storage facilities.

With a baffle FIBC bag, the unique construction means that those edges remain square and rigid, even when fully filled. As they retain their shape, you can maximize the capacity of both a baffle bag and a storage facility. It also makes them a more secure option, keeping contents in place during transit.

Basic bulk bags can be filled to capacity with certain heavy materials like sand, but they’re not ideal for storing and transporting finer materials. If you’re dealing with sensitive powders, a rigid baffle FIBC is a far better option for storage and transportation. Wherever your reason for switching from regular FIBCs, you’ll also benefit from significant cost savings when you use baffle bulk bags. With improved stackability, lower storage costs, and less waste, baffle bags can help you protect the bottom line.

As with standard FIBCs, many baffle bags can be reused. However, you’ll need to consider a few things before using a baffle bag more than once. The same rules as standard bulk bags apply here. Any baffle bag with a 5:1 safety rating should only be used once. If you plan on using a bulk bag more than once, you’ll need to purchase FIBC baffle bags with a 6:1 safety factor.

If your baffle bags are suitable for reuse, make sure they’re cleaned beforehand. You may need to be particularly thorough here, depending on the kinds of materials that were previously stored and transported in the FIBC. Replacing the container liner is also a must. It’s also important to conduct a full inspection of any bag before it’s reused elsewhere. Check for visible signs of wear and tear. While elements like labels and cord locks can be replaced, any evidence of fraying is a good clear sign that a bag should be retired and recycled.

Any baffle bag made from virgin polypropylene can be readily recycled. It’s fairly simple to reprocess this material, with the resulting resins used to make all manner of plastic-based products. In fact, polypropylene holds up particularly well to recycling. Unlike other materials, structural integrity isn’t really impacted by the process.

Standard bulk bags might be flexible and affordable, but they can easily lose their shape once filled to the brim with material. Unlike normal FIBCs, baffle bags maintain a uniform square shape when filled. This increases storage capacity and improves stackability, making them a good choice for compact facilities. They also work well logistically, with the rigid edges of a baffle bag preventing leaks and spillages in transit. By allowing you to make better use of your square footage and preventing material waste, the cost-saving benefits of FIBC baffle bags are obvious.

It’s also easy to adapt baffle bags to your needs. You can modify baffle bags in the same way standard FIBCs can be tailored, while a range of top and filling options broadens their applications further. Suitable for use in almost any industry, baffle bags are also readily recyclable, while those with a 6:1 safety factor rating can be reused.

If you’re looking to stamp out waste and embrace stackability, baffle bulk bags are the way forward. At Codefine, you’ll find a full range of baffle bags to meet your needs. Since 1957, Codefine has been at the forefront of the FIBC market, providing sustainable packaging to some of the largest companies on the planet. Interested in learning more about the benefits of baffle bags? Get in touch to discuss your requirements or find out more about our other products.